| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Feature | Lightweight, & Strong |

| Color | Black, etc |

| Usage | A Foundation reinforcement mat for improvement of load bearing capacities of weak soilsities of weak |

| Click to view more | |

Product Details

Performance

Optimum

Features

Long functional life

Advantage

Easy to Operate

The Geocell load support system stabilizes the selected infill and provides ecomincal solutions to unstable surface or base problems in three key ares :

- A Load distribution system over weak soils

- Base stabilization for paved surfaces

- surface stabilization for unpaved surfaces.

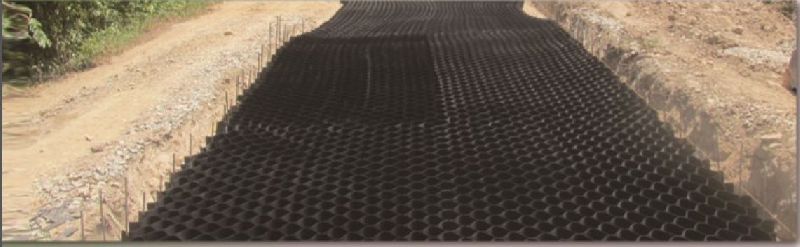

Subgrade Preparation

- Excavate and shape foundation soils.

- Ensure foundation soil meets minimum strength requirements through proof or other conventional method. If unacceptable foundation soils are encountered, excavate and replace with suitable quality material.

Separation Layer and Base Materials Installation

- When separation between subgrade soil and infill material is required, place geotextile over subgrade.

- If additonal base materials or engineered soils are requierd between separation geotextile and geocell, install the appropriate depth and compact to a minimum 95 percent standard proctor or 90-92 percent modified proctor test.

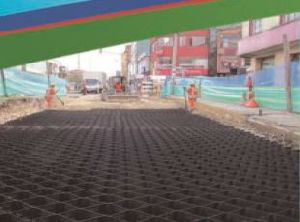

Geocell Panel Placement and Connection

- Position and expand geocell panels to the appropriate dimensions. Hold individual panels in their expanded positions with rebar J-Pins or wooden stakes. Join panels using traditional Stapling methods or connecting studs.

- Confirm each geocell paenl is expanded uniformly and correctly aligned. Nest panels along each joint to ensure adjacent geocell panels are flush at joint and adjoining cell are fully anchored. Alternate the installation of rebar J-Pins or wooden stakes to ensure each panel is Stable.

- Install rebar fixing or wooden stakes along the joint of each panel in every other perimeter cell to hld the geocell panels stable during infill. Alternate the installtion of rebar fixing pins or wooden stakes to ensure each panel is stable.

Exposed Aggregate or Engineered Infill

- Fill geocell with specified aggregate material progressively from front to back. Do not use an infill material with particle sizes greater than 65 mm.

- Overfill cells to a depth of approximately 50mm and level for exposed aggregate surfaces. Maintain the 50mm wear surface over geocell panels to prevent wear to the cell walls.

- Compact infill to a minimum of 95 percent Standard Proctor or 90-92 percent Modified Proctor test.

Base Stabilisation

- Overfill geocell to a depth of 25mm and compact to a minimum of 95 percent Standard Proctor or 90-92 percent Modified Proctor test.

- The wearing course may consist of asphalt/concrete/paver stones/gravel or grass stabilizer or other as specified. Install per engineer's specifications.

Details

- Site Access Roads.

- Permeable, Load-supporting Surfaces.

- Roadway Shoulders.

- Intermodal /port Facilities.

- Transportation/storage Yards.

- Stabilized Drainage Layer.

- Trails And Walkways.

- Track Ballast And Subballast Structures.

- Stabilized Base For Asphalt Or Modular Block Pavements.

- Boat Ramps / low Water Crossings.

- Foundation Mattresses And Pipeline Protection.

Looking for "Load Support Geocell" ?

Square Meter